Exploring Industrial Fans: Types, Applications, and Choosing the Right Fit

Industrial fans are essential components in various sectors, serving crucial roles in ventilation and air movement applications. These fans come in diverse types, each tailored to specific industrial needs.

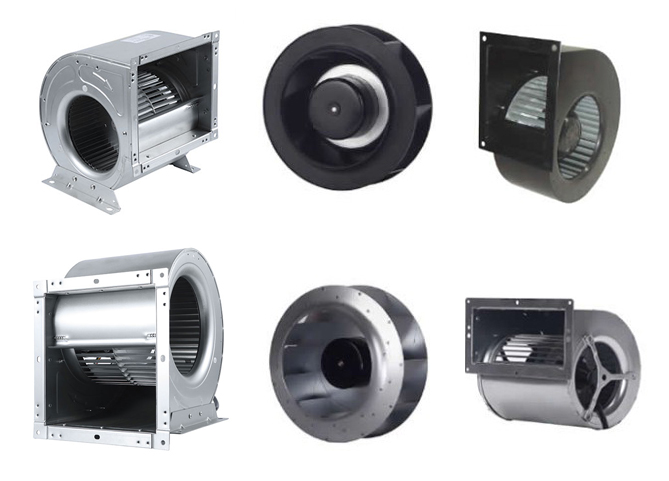

Centrifugal fans are one prevalent type, characterized by their ability to generate airflow perpendicular to the fan blades' rotation axis. They find extensive use in HVAC systems, manufacturing plants, and mining operations due to their robust performance and ability to handle high pressures.

Centrifugal fans are one prevalent type, characterized by their ability to generate airflow perpendicular to the fan blades' rotation axis. They find extensive use in HVAC systems, manufacturing plants, and mining operations due to their robust performance and ability to handle high pressures.

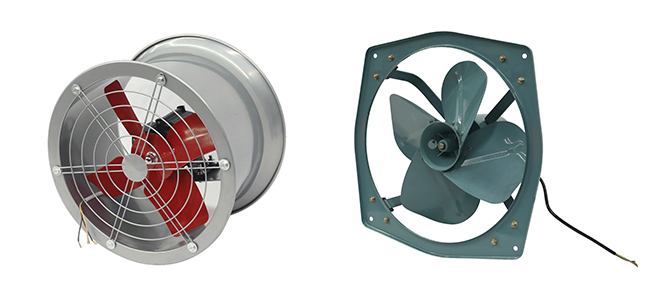

Axial fans, are designed to move air parallel to the shaft around which the blades rotate. Axial flow fans are suitable for applications requiring high airflow rates at low pressures, such as cooling electronic equipment, ventilating tunnels, and air-cooled heat exchangers.

In industries like chemical processing, pharmaceuticals, and food production, where hygiene and clean air are critical, special designs like sanitary fans are employed. These fans are constructed with materials that meet stringent cleanliness standards and are easy to clean and maintain.

Axial fans can be also use as the dust extractor fan, also known simply as a dust extractor or dust collector fan, is a device used to improve air quality by removing dust particles and other airborne contaminants from industrial and commercial environments. It typically consists of a fan or blower that creates suction, drawing in air laden with dust and directing it through a filtration system.

Dust extractor fans are commonly used in woodworking shops, metalworking facilities, construction sites, and any other industrial settings where dust and particulate matter are generated. Dust extractor fans play a crucial role in improving air quality, protecting workers' health, and ensuring compliance with occupational health and safety regulations.

When selecting industrial fans, several factors must be considered. Efficiency is paramount, as fans contribute significantly to energy consumption in industrial facilities. Noise levels are another concern, particularly in environments where low noise is crucial for worker comfort or regulatory compliance. Reliability and durability are also vital, ensuring continuous operation without frequent maintenance interruptions.

We offer customization options to suit specific operational requirements, including variations in size, materials, motor types, and control systems, also considering the flexibility in installation configurations and compatibility with existing infrastructure.

We offer customization options to suit specific operational requirements, including variations in size, materials, motor types, and control systems, also considering the flexibility in installation configurations and compatibility with existing infrastructure.

At our factory, we specialize in manufacturing ventilation equipment, including industrial fans. Our products address many of the shortcomings found in existing market offerings, providing significant advantages in terms of efficiency, noise reduction and reliability. The meticulous attention to detail ensures optimal performance even under challenging conditions, making them a preferred choice for industrial applications worldwide.

If you are interested in our industrial fans or have specific requirements, please feel free to contact us. We are committed to delivering tailored solutions that enhance operational efficiency and environmental comfort in your facilities.